Search This Supplers Products:RFID ReadersBarcode ScannersMobile ComputersRFID BarCode Solutions

How Does RFID Technology Make Manufacturing More Intelligent?

time2022/03/07

- This article will specifically introduce the application and advantages of RFID technology in manufacturing so that you can have a deeper understanding.

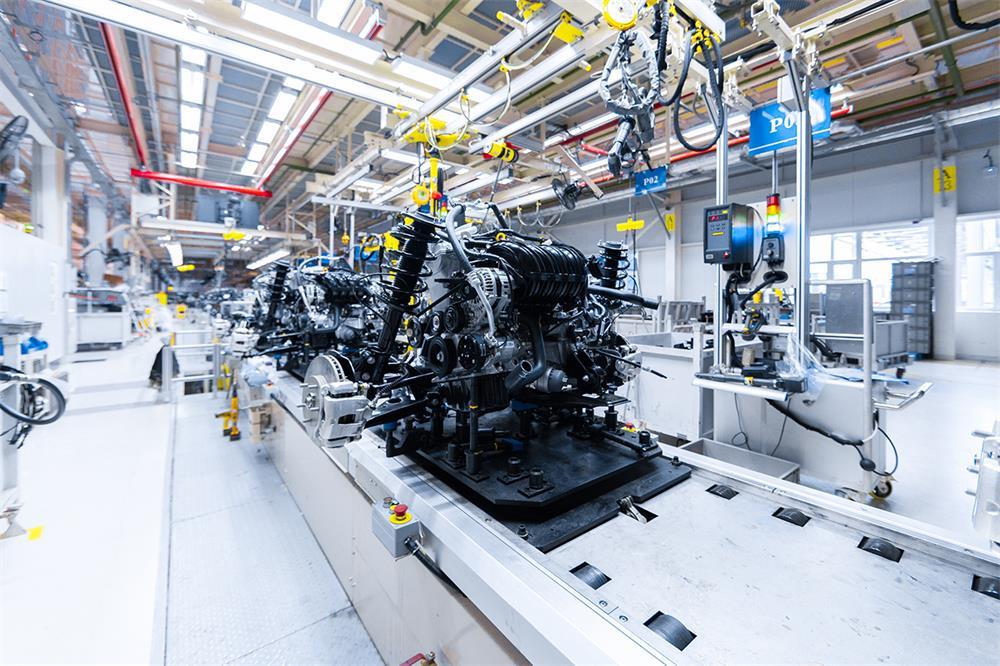

As the trend of industrial production automation becomes more and more obvious, intelligent production machinery and equipment have replaced most of the manual labor. Of course, to a certain extent, industrial production capacity is gradually improving.

In order to achieve intelligent production, we can implement manufacturing execution system management through radio frequency identification technology, including control of production execution, monitoring, and management. We can enter a deeper understanding by understanding the application and advantages of RFID technology in manufacturing.

Applications of RFID Technology in Intelligent manufacturing

RFID electronic tags are used for raw material management, they can track and record all attributes related to each part, including production process, next process, own color and size, and even quantity, flow direction, or customized customer information, which can be expanded to the finished product after assembly.

RFID technology can carry out refined production according to customer needs and gradually enter into customization when raw materials begin to flow into production chemical production. At the same time, the chip barcode is printed on the RFID electronic label, which is compatible with the old equipment and avoids the waste of assets.

RFID technology has the following advantages in intelligent manufacturing:

1. Automatic data collection does not require any contact, the whole process does not require manual intervention, and is not easy to damage;

2. RFID technology can collect the information of objects in the running state, and can identify multiple cards at the same time, which is easy to operate;

3. RFID technology is suitable for a series of requirements such as a harsh production environment, difficulty for personnel, large data storage, high real-time data transmission requirements, and reliable and effective data transmission.

Generally speaking, RFID has great application prospects for real-time data collection in the working environment of intelligent production, storage, and logistics. It has realized the integrated management of raw materials, factory manufacturing, sales, and customer demand.

All devices communicate with the acquisition server through the network, and the existing MES and the acquisition server interface through the database. This can reduce the difficulty of conversion of existing systems, clarify work responsibilities, facilitate future maintenance and troubleshooting, improve server security, reduce openness, maximize conversion and improve production efficiency.

In order to maintain the efficiency and accuracy of production, manufacturing enterprises have put forward higher requirements for the automation of production processes. It is difficult to accomplish such a complex task without a highly organized and integrated control system.

As the development direction of future manufacturing technology, intelligent production will have a profound impact on manufacturing models and manufacturing enterprises. As an automatic identification and acquisition technology, RFID makes production more intelligent.

RFID intelligent production adopts a novel, comprehensive and advanced production management structure, collects data layers through IoT sensors, and effectively manages the entire production line to achieve the best production effect.

As a professional pro RFID & barcode manufacturer, YANZEO has won unanimous praise from the industry with its leading R&D technology and excellent manufacturing technology. In order to strictly control the quality of products, we are equipped with a professional manufacturing team and a comprehensive quality control system. We also provide users with thoughtful one-stop service and develop effective solutions. If you are interested in our RFID products, please contact us immediately!