Search This Supplers Products:RFID ReadersBarcode ScannersMobile ComputersRFID BarCode Solutions

UHF RFID Technology Application In Production

time2022/10/21

- The application of UHF RFID technology in the production of enterprise materials is mainly divided into the following links, including procurement, production, warehousing, inventory management, outbound management and yard management.

Procurement Link

In the procurement chain, enterprises can achieve timely procurement and rapid response procurement through UHF RFID technology. Management is able to understand the supply status of the entire supply chain in real time, so as to better grasp inventory information, supply and production demand information, etc., timely procurement planning and management, and timely generation of effective purchase orders. Through the application of UHF RFID technology, you can purchase the exact materials at the exact time will not cause a backlog of inventory, and will not affect the production plan because of the lack of materials, so as to achieve reasonable procurement, that is, at the right time, choose the right product, at the right price, according to the right quality, and through the right supplier.

With the premise of information resources integrated through IOT technology, enterprises can realize the informationization of procurement internal business and external operation, realize the paperless of procurement management, improve the speed of information transmission, speed up the reaction speed of production decision, and finally achieve the unification of workflow, i.e. to take the purchase order as the source, from the supplier to confirm the order, delivery, arrival, inspection, storage and other aspects of the flow of purchase orders It is possible to carry out accurate tracking, and to select various procurement processes, such as direct warehousing of orders, or inspection and warehousing after the arrival quality inspection, etc. Meanwhile, in the whole process, it is possible to monitor and manage the planned status of procurement stock, the status of orders in transit, and the status of arrivals to be inspected, etc. Through the unified control of capital flow, logistics and information flow in the procurement process, we can achieve the optimal matching of total cost and total efficiency in the procurement process.

Production Process

The starting point of traditional enterprise logistics system in the warehouse or out of the warehouse, but in the logistics system based on UHF RFID, all the materials in the production process should have begun to achieve UHF RFID tags (Tag). As in general commodity logistics, most of the UHF RFID tags are used in the form of self-adhesive labels, which only need to be attached to the item packaging UHF RFID tags can be.

The most important thing in the production of enterprise materials is the UHF RFID tag information entry, which can be divided into four steps to complete.

1. Description of the corresponding item information, including the production department, completion time, production of each process and the person responsible, the use of the deadline, the use of target departments, item numbers, security levels, etc., UHF RFID tags comprehensive information entry will become a powerful support for process tracking.

2. Enter the relevant information of the items in the database into the corresponding UHF RFID tag items.

3. The item and the corresponding information editing, to get the original information and database of the item, which is the first step in the entire logistics system, but also the first link of UHF RFID intervention, you need to absolutely guarantee the accuracy and security of the information and UHF RFID tags in this link.

4. After completing the information entry, use the UHF RFID reader to confirm the information and check whether the information corresponding to the UHF RFID tag is consistent with the item information. At the same time, data entry is carried out, showing the completion time and the person who handles the UHF RFID tag information entry of each item. To ensure the uniqueness of UHF RFID tags, the information of the same products can be sorted and coded to facilitate the inventory of the same items.

Intake Link

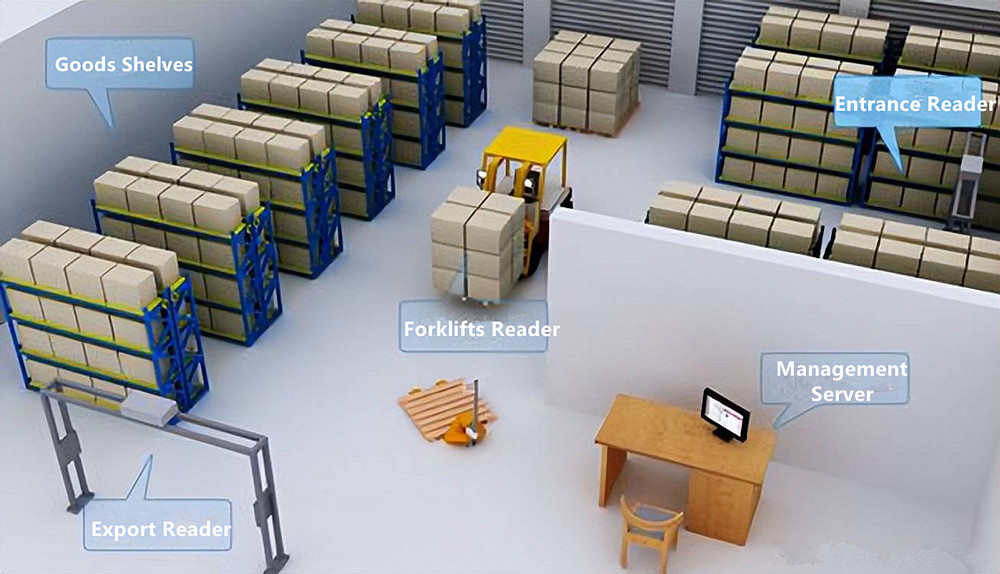

There are 3 basic elements in the traditional logistics system that are strictly controlled: handling personnel, items, and records. This process requires a lot of labor, time, and generally requires multiple layers of multiple checks to ensure accuracy. In the UHF RFID inbound system, these 3 links can be controlled efficiently and accurately through the UHF RFID information exchange system. In the UHF RFID inbound system, the UHF RFID tag of the item is identified by the reader at the inbound channel, and the information of the corresponding item is found in the database and automatically entered into the UHF RFID inventory management system. The system records the incoming information and verifies it. If it is qualified, it will enter the inventory information, and if there is any error, it will prompt the error message, issue an alarm signal and automatically prohibit the incoming inventory.

In the inventory information system of UHF RFID, through the function extension, it can directly guide the RF terminal on the equipment of forklift and stacker, select the empty cargo space and find out the best way to reach the empty space. The reader confirms that the goods are in place and then updates the inventory information. After the goods are in stock, the inventory list can be printed through the UHF RFID system printer, and the responsible person can confirm it.

Inventory Management Link

After the goods are warehoused, you also need to use the UHF RFID system for inventory inspection and management, this link includes regular inventory checks of the classified goods through the reader to analyze the changes in the inventory of goods; when the goods are displaced, the UHF RFID tags of the goods are automatically collected through the reader, and the corresponding information is found in the database, and the information is automatically entered into the inventory management system to record the goods With the help of UHF RFID system, the manual workload in traditional inventory management is greatly reduced, and safe and efficient inventory management is realized.

As UHF RFID realizes the automation of data entry, no manual checking or barcode scanning is required during inventory, which can reduce a lot of labor and material resources and make the inventory faster and more accurate. Inventory control using UHF RFID technology can accurately grasp inventory information in real time, from which we can understand the demand pattern of each product for timely replenishment and change the inefficient operation, while improving inventory management capabilities, reducing average inventory levels, and effectively reducing inventory costs through dynamic real-time inventory control.

Outbound Management Link

In the management of UHF RFID outbound system, the management system automatically determines the pickup area and the optimal pickup path according to the item's outbound order requirements. After scanning the UHF RFID tags of goods and cargo space, it confirms the outgoing goods and updates the inventory at the same time. When the goods arrive at the exit channel, the reader will automatically read the UHF RFID tag and pull out the corresponding information in the database, and compare with the order information line, if it is correct, the goods can be discharged, and the inventory of goods will be reduced accordingly; if there is an abnormality, the storage management system will show prompt information to facilitate the staff to deal with.

Yard Management Link

Goods in the warehouse to the goods yard after the need for regular inspection, and the traditional inspection methods consume a lot of manpower and time. With the help of UHF RFID system, it is much easier to check the yard. Using the UHF high-frequency radio frequency system can be a 10-meter radius of the UHF RFID tags for automatic identification, the UHF RFID system reader will first batch of items of the same UHF RFID tag identification, while the corresponding database tag information; then these information and the database for comparison, to see whether there are abnormalities in the yard of all kinds of items.